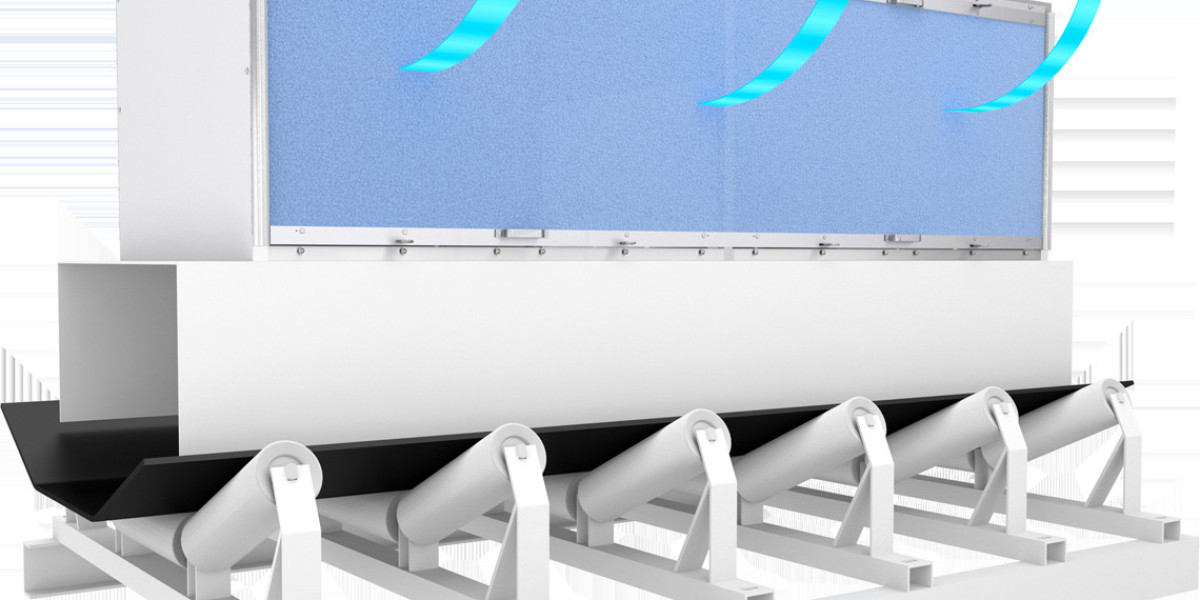

In any conveyor system, belt tracking is critical to ensure smooth, efficient, and safe operation. Misaligned belts can lead to excessive wear, damage to components, spillage, and costly downtime. That’s where belt trackers come in — essential devices designed to keep your conveyor belts centered and running true. Choosing the best belt trackers conveyor can make a significant difference in system performance and maintenance costs.

The best belt trackers conveyor are engineered to automatically detect and correct belt misalignment in real time, preventing problems before they escalate. They typically use pivoting rollers or guide mechanisms that respond to the slightest change in belt position, gently nudging the belt back on track without interrupting operation.

One of the top names in this space is Martin Engineering, known for their high-performance belt tracking systems like the Martin Tracker™. These trackers come in standard, heavy-duty, and reversible models, making them suitable for various conveyor types and loads. Martin’s designs are rugged, low-maintenance, and built to perform in harsh environments — from mining and quarrying to cement and bulk material handling.

Another reliable brand is Flexco, offering trackers like the PT Smart™ and PT Max™, which are ideal for both light- and heavy-duty applications. These trackers feature unique pivot-and-tilt designs that provide fast and responsive correction while minimizing belt edge damage.

When selecting the best belt trackers conveyor, consider the belt width, operating conditions, material type, and load requirements. A good tracker should be easy to install, adjustable, and compatible with both troughing and return sides of the conveyor. Also, look for corrosion-resistant materials and heavy-duty components if your system operates in demanding environments.

Proper belt tracking isn’t just about keeping the belt straight — it’s about optimizing productivity, extending the life of your conveyor components, and ensuring the safety of your operation.

In summary, investing in the best belt trackers conveyor is a smart move for any facility that depends on conveyor systems. Brands like Martin Engineering and Flexco offer top-tier solutions to keep your belts aligned, your materials moving, and your downtime to a minimum.